Project Overview

TPS360 was selected by GWR to refurbish the flooring and inspection pit walls at their Laira Depot in Plymouth. The project involved removing old flooring, deep cleaning the surfaces, and installing new, slip-resistant resin systems to improve safety and durability.

Scope of Work

Preparation

The existing flooring was mechanically removed, followed by thorough surface preparation. This included high-power jet washing of the pit walls to remove over 40 years of contaminants, ensuring a clean surface for the resin application.

Products Used

Challenges

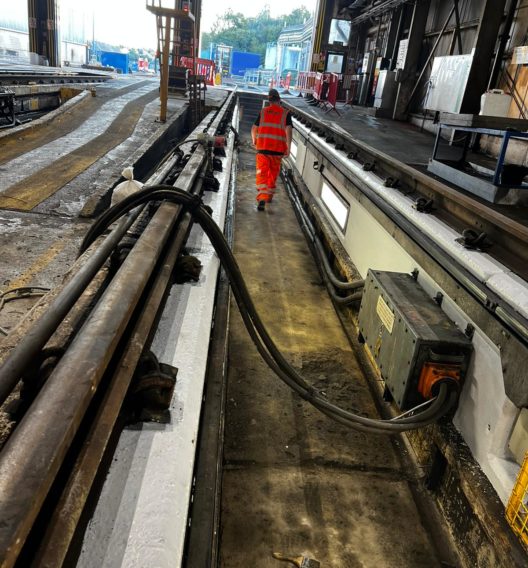

The project was carried out in a live, operational depot. TPS360 worked in phases during off-peak hours to minimise disruption. The team also tackled tight spaces within the inspection pits, using specialised equipment for a smooth and efficient process.

Quality Management

TPS360 followed strict quality management procedures, from planning to installation. Each phase was closely monitored, ensuring the correct application of the resin systems. Final inspections were conducted to ensure the flooring met GWR’s standards for safety and durability.

Results

The project was completed on time, providing GWR with a safer and more durable working environment. The new flooring system is designed to handle the daily demands of the depot, ensuring long-lasting performance.

Scott Barclay, Operations Director at TPS360, said…

“This project highlights our expertise in delivering flooring solutions in challenging, live environments. We worked closely with GWR to ensure minimal disruption and a top-quality finish that will last for years.”