TPS360 boast a vast experience and high credibility within the polished concrete sector and has worked in retail, manufacturing, aerospace, warehousing, education and office space.

Many companies and contractors are unaware of the raft of benefits that polished concrete offers as a durable, resistant flooring solution for industrial and commercial settings such as hangars, warehouses and factories. It is for this reason that TPS360 provide expertise and assistance with specification as part of our process.

Polishing concrete is a multi-step process where the concrete floor is mechanically ground, honed and polished with bonded abrasives to cut the surface. With each cut, the floor is refined to achieve a specified level of appearance and treated with a penetrant chemical known as a ‘hardener’ to help harden and dustproof its surface.

Concrete polishing usually involves a minimum of four grinding steps, using progressively finer diamond polishing pads. Dyes designed for concrete polishing is often applied to add colour as well as other options such as scoring, creating line markings and demarcations, and other designs. Polished concrete is a “green” LEED-approved flooring system which offers a multitude of benefits, making it a popular choice for both industrial and commercial spaces.

Here are some of its key advantages:

TPS360 deliver all types of polished concrete flooring systems of many different specifications. This includes existing, and newly laid concrete surfaces, as well as polished screed overlay systems, laid and polished in-house. Projects we successfully manage range in size from 100m2 to 24,000m2, covering all sizes of retail spaces to multi-aircraft hangars.

We offer installation, preparation, concrete repairs and surface treatment alongside our concrete polishing services to provide a full single-source solution.

We believe TPS360’s credibility in our sector is backed up by years of experience and all our operatives attend installation training at Husqvarna and Smartfloor polished concrete academy training.

We have spent the last ten years equipping industrial and commercial enterprises with the polished concrete flooring solutions they need, to get the opportunities they deserve. Furthermore, we also offer aftercare and maintenance products so that companies can continue to protect their commercial flooring with the perfect TPS360 solution.

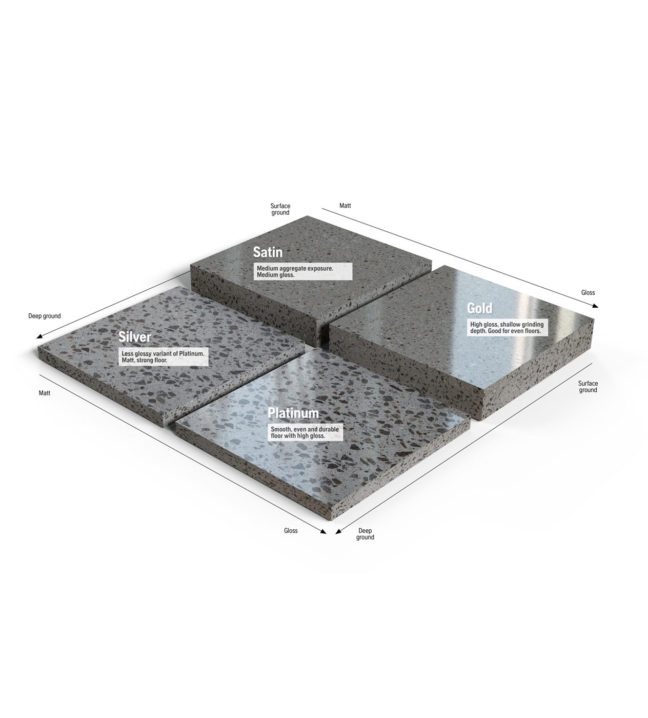

Husqvarna Superfloor™ is available in four different surface finishes and degrees of aggregate exposure: Satin, Silver, Gold and Platinum. It’s the grinding depth and the number of polishing steps that differentiate the finishes.

Besides the four concepts, Satin, Silver, Gold and Platinum, you can also have a custom finish that matches your specific preferences for aggregate and gloss.

What makes Husqvarna Superfloor™ truly exceptional is the level of detail and craftsmanship that goes into each finish. The grinding depth and the number of polishing steps are expertly tailored to bring out the best in each finish, ensuring that you get a flooring solution that not only looks stunning but also performs exceptionally well.

Husqvarna Superfloor™ Satin

Satin finish is an indoor application for retail areas, shop fronts and indoor public places with semi-exposed aggregate and medium gloss appearance. The result is a floor that offers functionality and low maintenance but is still aesthetically pleasing.

Husqvarna Superfloor™ Silver

Silver is a matte variant of Platinum. Since the grinding depth is the same and the aggregate is widely exposed, the floor is very strong. Silver is a good choice when you do not need or want a highly reflective floor.

Husqvarna Superfloor™ Gold

Gold entails that the floor is not ground as deep as Platinum. However, the floor is polished to the same gloss. Gold can therefore be a good choice for concrete floors that are already smooth and even.

Husqvarna Superfloor™ Platinum

Platinum is the best of the best. By repeatedly grinding and polishing the floor, you get a smoother, more even floor with more aggregate exposure and unmatched resistance to wear. Platinum is the most popular surface finish and is a good choice for most applications.

Meet our specialist

Mark Jackson, our Sales Director, has over 30 years experience in polished concrete gained at HTC, SIG, PPC and most recently in the last 3 years, at TPS360.